The Evolution of SMA Connectors: History, Standards, and Applications

Introduction

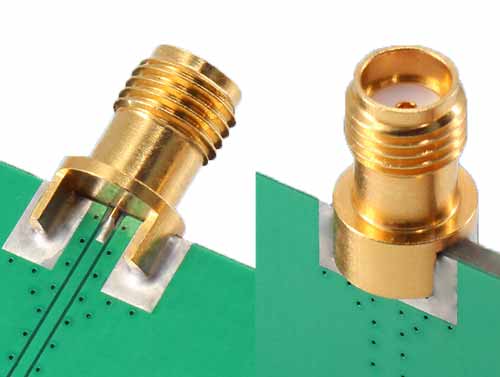

In the realm of radio frequency (RF) and microwave engineering, connectors play a pivotal role in ensuring signal integrity and system reliability. Among the myriad of RF connectors, the SMA (SubMiniature version A) connector stands out for its compact design, high-frequency performance, and widespread adoption across various industries. This article delves into the history, standards, and applications of the SMA connector, highlighting its significance in modern communication systems.

Historical Background

The SMA connector was developed in the 1960s to meet the growing demands of high-frequency applications. Initially designed for military and aerospace purposes, its robust performance and compact size led to widespread adoption in commercial sectors. The connector’s threaded coupling mechanism ensures a secure connection, making it suitable for environments where vibration and mechanical stress are concerns.

Technical Specifications

- Impedance: 50 ohms

- Frequency Range: DC to 18 GHz (standard), with some versions supporting up to 26.5 GHz

- Coupling Mechanism: Threaded

- Material: Typically brass with gold plating

- Durability: Rated for up to 500 mating cycles

Variations and Standards

Over time, several variations of the SMA connector have been developed to cater to specific applications:

- RP-SMA (Reverse Polarity SMA): Designed to prevent users from connecting unauthorized antennas to wireless devices, commonly used in Wi-Fi equipment.

- 3.5mm and 2.92mm Connectors: Precision connectors compatible with SMA but supporting higher frequencies up to 34 GHz and 46 GHz, respectively.

- IEC 60169-15: The international standard defining the mechanical and electrical characteristics of SMA connectors.

Applications

SMA connectors are ubiquitous in various industries due to their reliability and performance:

- Telecommunications: Used in cellular base stations, antennas, and RF modules.

- Aerospace and Defense: Integral in radar systems, communication equipment, and electronic warfare systems.

- Test and Measurement: Found in network analyzers, spectrum analyzers, and other RF testing equipment.

- Consumer Electronics: Employed in GPS devices, Wi-Fi routers, and IoT devices.

Advantages of SMA Connectors

- Compact Size: Suitable for applications with space constraints.

- High-Frequency Performance: Maintains signal integrity at microwave frequencies.

- Mechanical Stability: Threaded coupling ensures a secure and vibration-resistant connection.

- Versatility: Compatible with various coaxial cables and adaptable to different configurations.

Considerations for Use

While SMA connectors offer numerous benefits, certain considerations should be kept in mind:

- Mating Cycles: Limited to approximately 500 cycles; excessive mating can degrade performance.

- Torque Specifications: Proper torque should be applied during installation to prevent damage.

- Compatibility: Care should be taken when mating SMA connectors with precision variants to avoid damaging sensitive components.

Global Sourcing and Shipping Advantages

For businesses and engineers sourcing SMA connectors, Shipping to Japan where tariffs are cheaper than China presents a strategic advantage. Japan’s favorable trade agreements and lower import duties can result in cost savings and streamlined logistics, making it an attractive destination for procuring high-quality RF components.

Conclusion

The SMA connector’s enduring presence in the RF industry is a testament to its robust design and adaptability. From its origins in military applications to its widespread use in modern communication systems, the SMA connector continues to be a cornerstone in ensuring reliable and efficient signal transmission. As technology advances and the demand for high-frequency applications grows, the SMA connector’s relevance and utility are poised to remain strong.