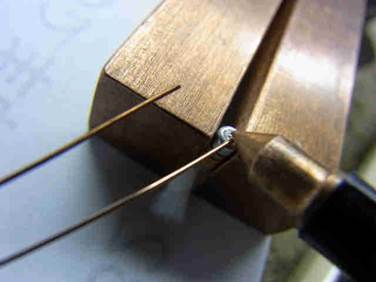

Cu φ0.3 / CU φ0.3 _2

Welded at 6.5V 1.6mS.

When the pulse width was increased from 1.6mS to 1.8mS,the copper wire was melted and buried in the resistance solder.

I used it by cutting it so that it can grip 1 mm of the resistance end,

but it is recommended to make a dedicated electrode

that can firmly grip the resistance electrode part.

Spot Welder:

HSW-03A

Electrode:

HSW-EB1